BUSINESS

Business Overview

Automatic welding equipment

We have established the basic concept and data for welding automation,

and are developing related technologies as it is highly likely to

manufacture and commercialize welding automation equipment.

- It is possible to more effectively improve existing robot welding in the BIG3 heavy industries, chemical plant, and shipbuilding and marine specialized fields.

- It is suitable for the rapidly changing market environment needs (fourth industry, smart factory, shipyard manpower supply and demand problems).

- Currently, we are developing an automatic steel pipe welding system with an automatic tracking device for welding fusion points in the improvement part for digitalization of feasible ship fittings with a clear recognition of the manpower problem in shipyards, including the Ulsan region.

We have established a welding automation technology coaching program to secure the soundness of welding quality by welding engineering with a difference compared to other companies since the development has now been completed and commercialization can be realized.

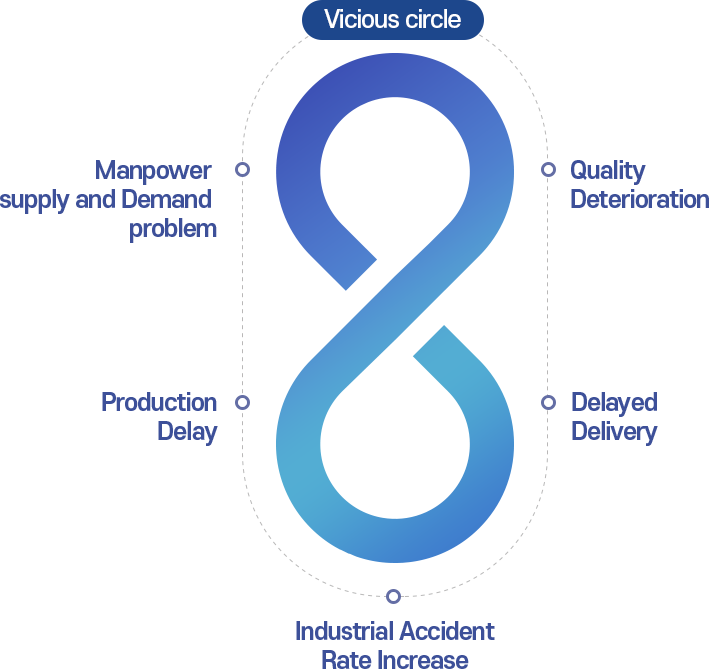

Why do they need an automated welding facility system?

A vicious cycle occurred due to manpower procurement problems against the increasing order volume of BIG 3 shipyards

- Manpower supply and

Demand problem - Production

Delay - Industrial Accident

Rate Increase - Delayed

Delivery - Quality

Deterioration

Crisis status of the shipbuilding and welding industries

- Primary vendors of shipbuilding equipment are in a situation where it is difficult to prepare for the long term on their own due to the burden of technology development investment and lack of research manpower.

Overcoming the crisis in the shipbuilding and welding industries

- ㆍApply advanced automotive welding technology.

- ㆍPromote the development of an outline for improving welding productivity.

- ㆍEarly establishment of technological innovation infrastructure.

PR VIDEO

PR video of

CHANGKUM corporation

Value proposal of welding automation technology

- - Productivity can be improved by shortening the production time of the process

- - High-precision work can improve customer product quality

- - The customer's manpower shortage problem can be solved by automating the process,

Material name STPG 370 / pipe diameter 400a,300a,200a

Work method: Welding automation machine flange welding type (inside/outside)

Material name STS 304L / pipe diameter 200a, SCH 40

Work method: Welding automation machine CAP/PIPE (back bead/inner bead) pressure purging

Result of product development

CO2 automatic welding driving test

| DN(A) | OUT | mm | sec |

|---|---|---|---|

| 200 | 219.1 | 688.0 | 57.3 |

| 250 | 273 | 857.2 | 71.4 |

| 300 | 323.8 | 1016.7 | 84.7 |

| 350 | 355.6 | 1116.6 | 93.0 |

| 400 | 406.4 | 1276.1 | 106.3 |

| 450 | 457 | 1435.0 | 119.6 |

| 500 | 508 | 1595.1 | 132.9 |

| 550 | 559 | 1755.3 | 146.3 |

| 600 | 610 | 1915.4 | 159.6 |

| 650 | 660 | 2072.4 | 172.7 |

| 700 | 711 | 2232.5 | 186.0 |

Tig automatic welding driving test

| DN(A) | OUT | mm | sec |

|---|---|---|---|

| 200 | 219.1 | 688.0 | 229.3 |

| 250 | 273 | 857.2 | 285.7 |

| 300 | 323.8 | 1016.7 | 338.9 |

| 350 | 355.6 | 1116.6 | 372.2 |

| 400 | 406.4 | 1276.1 | 425.4 |

| 450 | 457 | 1435.0 | 478.3 |

| 500 | 508 | 1595.1 | 531.7 |

| 550 | 559 | 1755.3 | 585.1 |

| 600 | 610 | 1915.4 | 638.5 |

| 650 | 660 | 2072.4 | 690.8 |

| 700 | 711 | 2232.5 | 744.2 |

Non-destructive testing